Structural Design & Engineering

Composite Design & Engineering Services

Stress Analysis: Aero Optimal Ltd was involved in the concept configuration, optimisation & weight saving work packages of the forward and aft fuselage composite structures of the A350XWB shells.

Design: In support of the A350XWB metallic & composite engineering, we have provided the associated Catia 2D drawing sets with BOMs & 3D models inclusive of Fibresim content. Also, a compilation of detailed weights/inertia/CG reports per assembly for inclusion in the aircraft weights model.

Recent Experience (2006 to 2017)

Our experience in the design, analysis and optimisation of lightweight structures (Composite & Metallic) such as wing, fuselage, high lift and control devices enabled us to work directly with Airbus' core engineering team in technical coaching, concept and detail design development of the A350 XWB-900 &-1000 passenger aircraft.

A350 XWB-900 Cabin Engineering Airbus Group Inc. USA (2015-2017)

Supporting Airbus Group Inc to develop and certify A350XWB galleys and monuments.

Check stress analysis and validation reports (team of stress engineers at B/E Aerospace, UK)

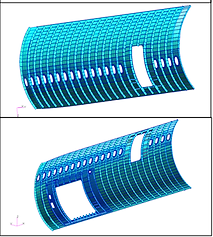

Engineering support to Airbus America, A350XWB-1000 side shells & door surrounds (2012-2015)

Engineering support to Airbus America Engineering for developing A350XWB-1000 fwd fuselage S13/14 side shells and Pax & Cargo door surrounds structures.

Stress (ISAMI and NASTRAN/PATRAN)

-

CSPS analysis of far-field skin/stringers

-

Frames and stringers cut analysis.

-

DFEM for frames analysis

-

Stringers de-bonding and skins perforation

-

GFEM shells definition and load extraction

Design (CATIA V5)

-

LH & RH skins / stringers design principal & drawings

-

LH & RH orbital joint design principal & drawings

-

Integration activities of skins/stringers, frames, clips, and shear webs into VPM

-

Corner fittings design for the floor-to-side shell attachments

Definition phase (Mat A) of A350XWB-1000 aft fuselage Shells (2011 - 2012)

Configuration, pre-sizing and maturity “A” sizing of the aft fuselage Skins/stringers, frames, and clips.

Specific sizing activity of CFRP fuselage structure and a variety of trade studies for the A350XWB-1000 variant. Pre-sizing, overall optimisation and harmonisation of internal load distribution of the CFRP Aft fuselage structure. Validation of optimised sizing results of the upper and lower side shells.

Skins and Stringers sizing analysis:

-

Local, General and Post buckling

-

Stringers de-bonding

-

Damage Tolerance

-

Frame-cut Large Damage capability

Frames and Clips sizing analysis:

-

Short Clips Sizing

-

Long Clips Sizing

%20of%20A350XWB-1000.png)

Detail sizing and justification stress reports of Upper & Lower shells structures (2010-2011)

A350XWB-900 AFT fuselage, preliminary sizing & justification stress report of upper and lower shells.

Preliminary stress justification reports of status Mat 'C.'

Upper shell: Skins and Stringers sizing analysis

-

ISAMI CSPS Calculations

-

General Buckling Analysis (ISAMI DFEM)

-

LDC Analysis (GFEM and ISAMI DFEM)

-

Stringers de-bonding, Rib-bay buckling and Cut-out analysis

Frames and Clips sizing

-

ISAMI Composite Frames Analysis

-

Long and Short Clips Analysis

NASTRAN/PATRAN DFEM "Upper Shell"

-

Antennas Surround Structures

-

Interface Frames and Skins Analysis

-

Dorsal Fin interface Analysis & Cut-outs

Lower shell: Skins and Stringers Analysis

-

ISAMI CSPS Calculations

-

General Buckling Analysis (ISAMI DFEM)

-

LDC Analysis (GFEM and ISAMI DFEM)

-

Stringers de-bonding, Rib-bay buckling and Cut-out analysis

Frames and Clips sizing

-

ISAMI Frames Analysis

-

Clips sizing analysis (short clips and shear ties sizing)

Integration support to Airbus America for A350 XWB-900 forward fuselage section side shells (2008-2014)

Engineering support to Airbus America for developing A350XWB-900 Fwd fuselage S13/14 side shell structures.

Design and stress analysis of section 13/14 side shells excluding Pax and Cargo doors.

Stress (ISAMI and NASTRAN/PATRAN)

-

CSPS analysis of complete far-field skins/stringers

-

Frames and stringers cut analysis.

-

DFEM for frames analysis

-

Stringers de-bonding and skins perforation analysis

-

GFEM definition of side shells and load extraction

Design (CATIA V5)

-

LH & RH skins/stringers design principal & drawings

-

LH & RH orbital joint design principal & drawings

-

Integration activities of skins/stringers, frames, clips, and shear webs to VPM

-

Corner fittings design for the floor-to-side shell attachments

Validation of CFRP door surround structures design and analysis (2010)

A350XWB-900 Aft fuselage section 16/18 PAX, BULK and CARGO doors surround structures.

Door surround skins and stringers with backup structures sizing.

-

Supporting Airbus section 16/18 side shells team in checking the supplier validation reports concerning sizing methodology.

-

Detail check stress analysis of PAX, BULK and CARGO doors surround structures DFEM (detail finite element model) and providing recommendation proposals to improve the FE models for static and buckling analysis (MSc Nastran SOL 101 & 105 analyses).

Concept & definition phase of -900 fwd & aft structures (2007-2010)

A350XWB -900 fuselage Fwd & Aft (sections16/18 & 13/14) Concept and Mat "A “.

Technical coach to the core engineering team and fuselage optimisation proposals for the A350XWB Fwd and Aft fuselage (sections16/18 & 13/14).

2007-2009: Technical coaching of Fwd & Aft section stress team for the definition design concept, pre and target sizing of CFRP fuselage structure. Some of the main tasks are as follows:

-

Stringers pitch definition.

-

Stringers geometries definition.

-

Skins and stringers thickness & layups definition.

-

Door surrounds skin layups definition.

-

Frames layup definition

-

Longitudinal & circumferential joint layups and thickness distribution.

-

Rear pressure bulkhead intermediate and detail FEM

-

Small & large Cut-out sizing

-

Window belt layups and pre-sizing definition.

-

Longitudinal and Orbital joints layups definition

2009-2010: Weight-saving optimisation studies of Fwd and Aft fuselage sections shell structures (NASTRAN/PATRAN and ISAMI).

Presentation of the weight-saving and optimisation design philosophy proposal of skins and stringers

Overall assessment of A350 CFRP wing & pre-sizing of CFRP upper cover (2006-2007)

A350XWB Wing Upper Cover (Wing Upper cover) Structure.

A350 wing (upper cover skins and stringers assessment, Mandatory Passage Hole)

-

Preliminary design and stress study (FE & Analytical) of the stringer's mandatory fuel passage hole and its effect on the skins/stringers of the A350 CFRP wing structure. Performed linear and non-linear analysis of skins/stringers with different MPH shapes of various local reinforcement shapes and reported various stress concentration factors for the three types of studies resulting in significant weight saving.

-

Review the complete wing box GFEM model (MSc NASTRAN/PATRAN) and modify the upper CFRP cover's geometry, mesh, and layups/properties.

-

Sub-structure static stress analysis of the upper cover (IFEM) with a detailed representation of the skins/stringers design leads to a more accurate definition of a load path and higher weight efficiency.

-

Overall static/buckling analysis of the CFRP upper cover and comparison of result to conventional boom represented FE model of the wing.